If Kaminak is lucky the oxides will prove to be a economic gold project on their own and provide some early cash-flow for future expansion into the sulfide facies rock.

[box type=”info” align=”aligncenter” ]Disclaimer: This is an editorial review of a public press release and not an endorsement. It may include opinions or points of view that may not be shared by the companies mentioned in the release. The editorial comments are highlighted so as to be easily separated from the release text and portions of the release not affecting this review may be deleted. Please view original release here.[/box]

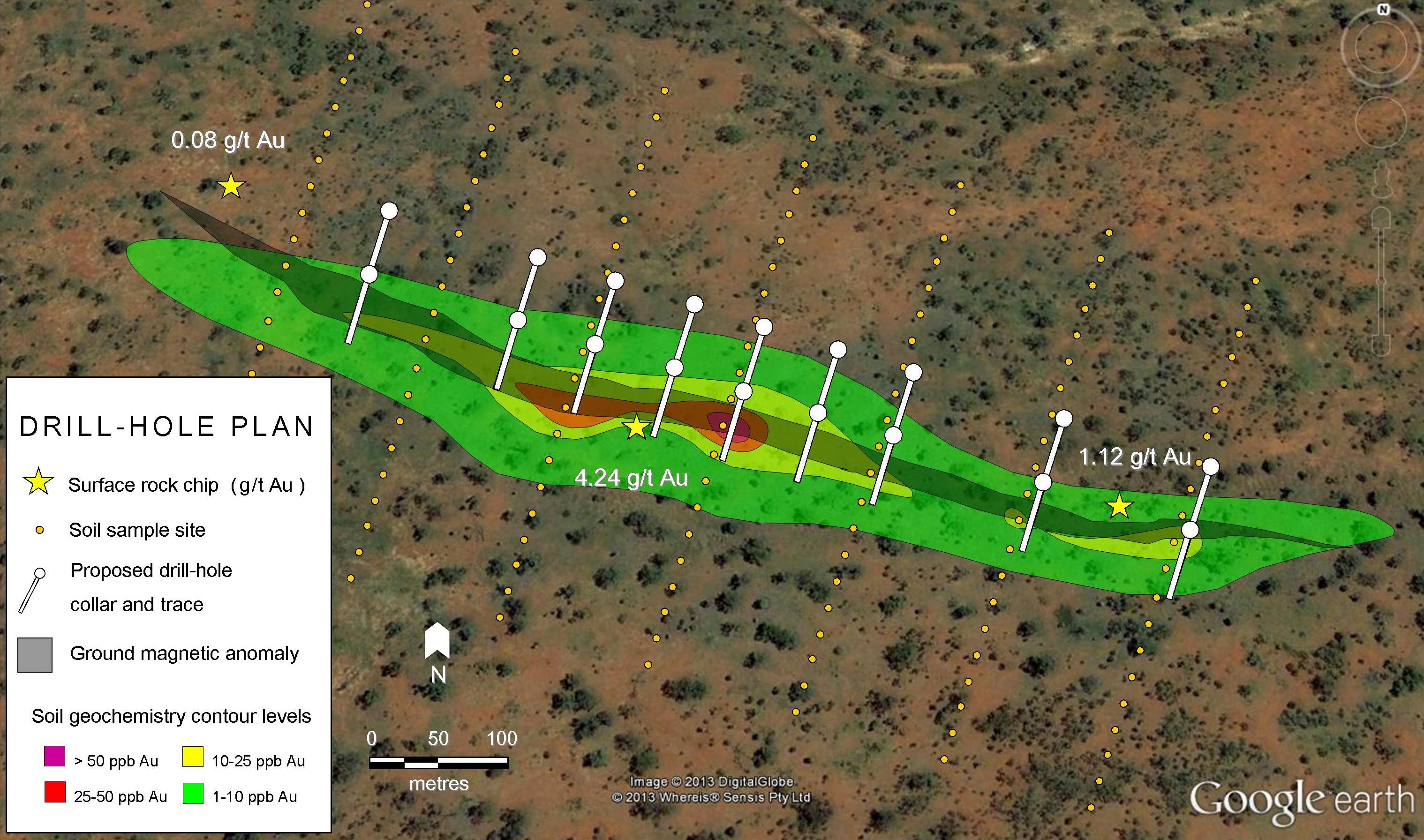

VANCOUVER, BRITISH COLUMBIA–(Marketwired – Dec. 2, 2013) – Kaminak Gold Corporation (TSX VENTURE:KAM) today announced the results of the first phase of a comprehensive metallurgical test work program at the Coffee Gold Project, Yukon, that will provide process input data for the updated NI 43-101 Mineral Resource Estimate scheduled for completion in the 1st Quarter of 2014, which will in turn lead into the initiation of a Preliminary Economic Assessment (‘PEA’). The primary objectives of the 2013 metallurgical program were to test the potential for heap leach processing of Oxide and Transitional facies at Supremo and Latte, two of the largest deposits discovered to date at Coffee, at variable crush sizes (0.5″, 1.0″ and 6″) and to establish representative gold recovery rates from cyanide soluble gold assaying for Oxide, Transitional and Sulphide facies mineralization at various depth profiles across the Coffee deposits.

[box type=”note” align=”aligncenter” ]

The last time we talked about Kaminak’s Coffee Project we discussed the advantages of having oxide-hosted gold mineralization over sulfide-hosted mineralization. This release is a perfect opportunity to compare the processes involved in extracting gold from each since Kaminak has performed heap leach tests on both its oxide and sulfide mineralized ore.

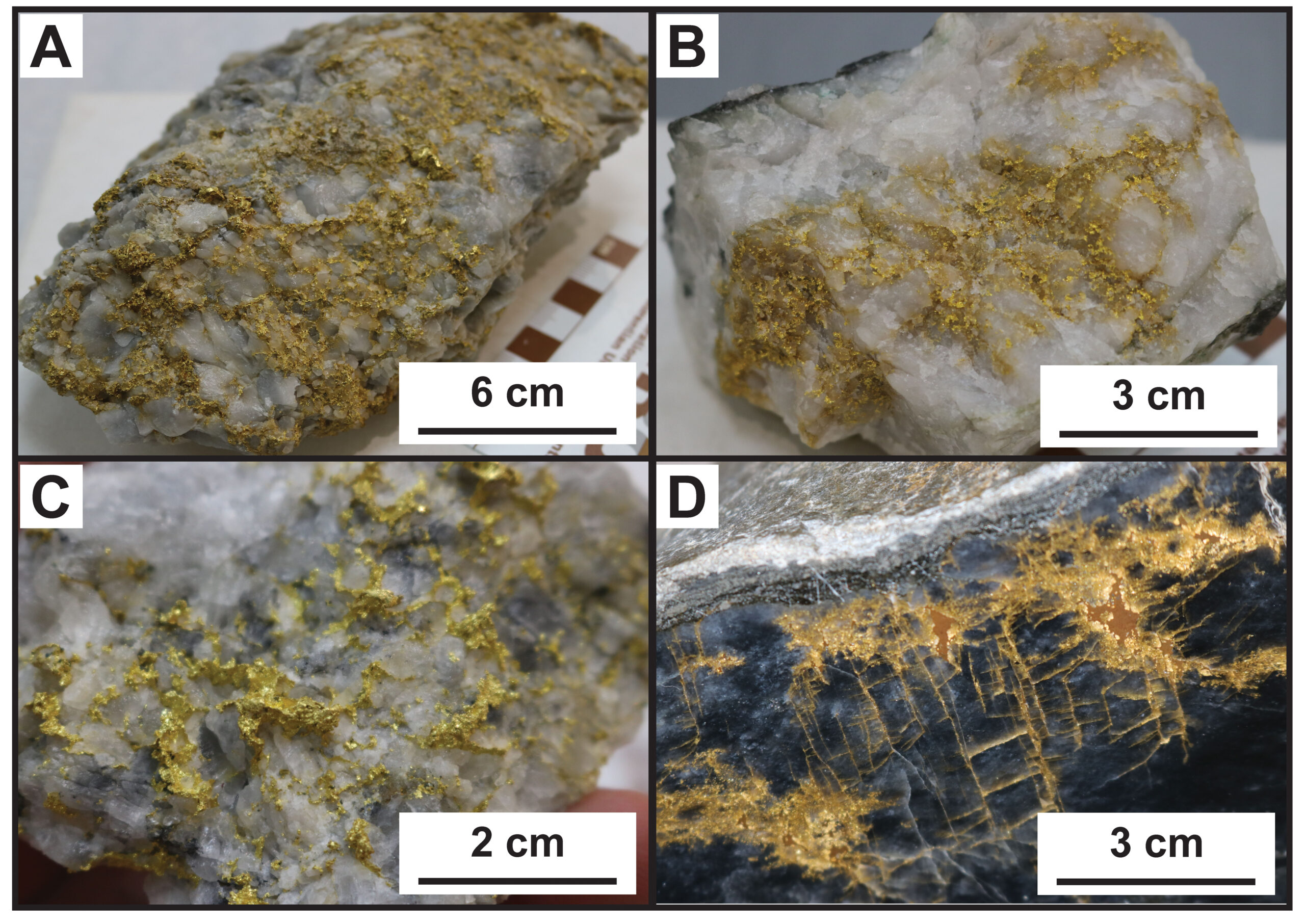

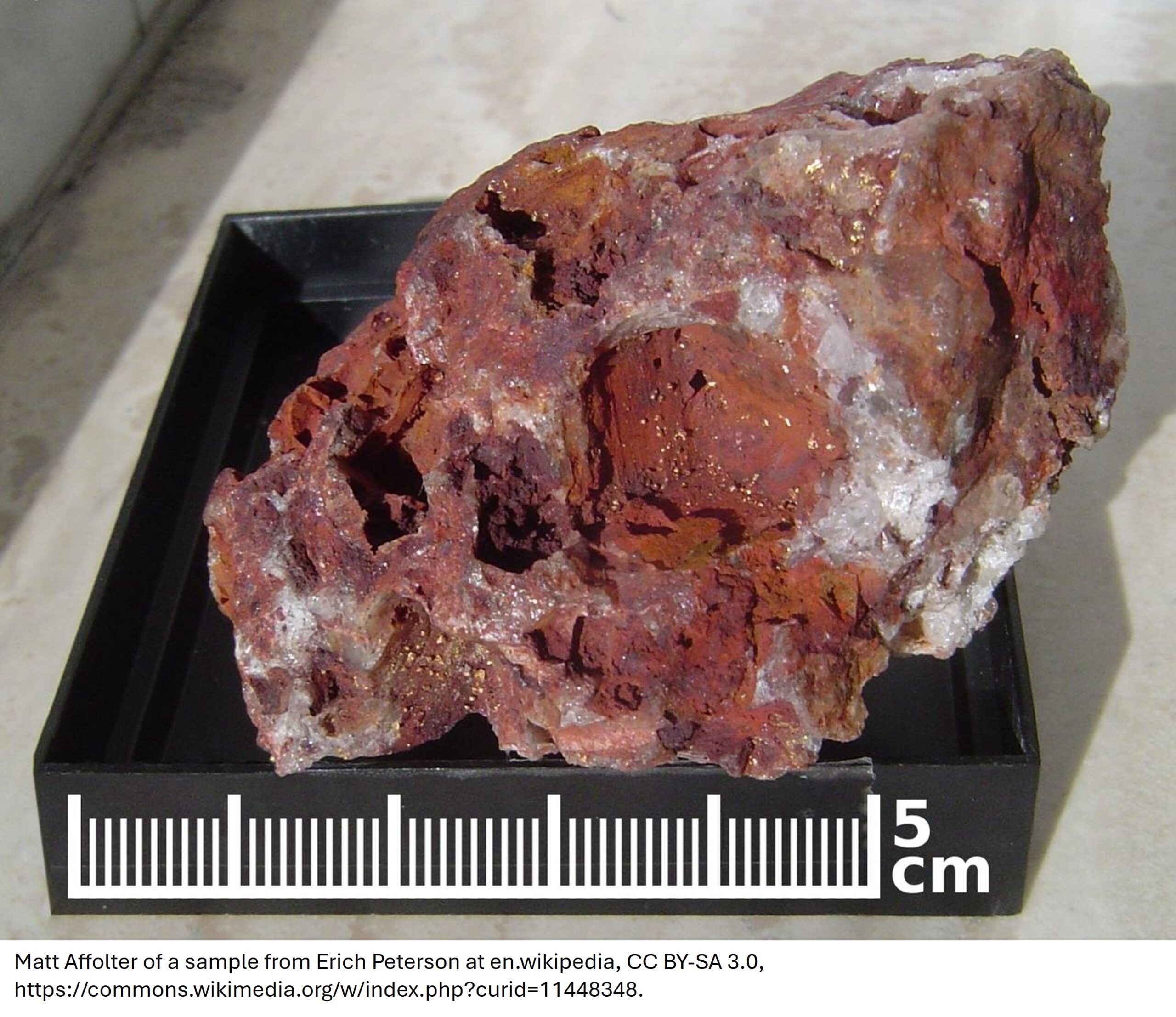

Oxides minerals include iron oxides like hematite (Fe2O3) and are often the result of the weathering of sulfide minerals like pyrite (FeS2). The weathering of these sulfides effectively liberates the small gold particles trapped within them, making them more available to the cyanide solution during extraction.

The extraction of gold trapped within sulfides requires usually involves a lot more energy and infrastructure.

[/box]

Highlights from this work include:

- Column leach gold recoveries of 90% to 92% on 1″crushed material from drill core composites of representative Oxide material from each of Latte and Supremo were achieved within 40 days.

- All of the samples leached very rapidly with 81.6% and 81.0% gold recovery after ten days leaching of the 1 inch Oxide crushed material from Latte and Supremo respectively.

- Column leach test work was conducted under simulated cold climate conditions by Kappes, Cassiday and Associates, industry leading experts in heap leach processing. Agglomeration was not required and low reagent consumption was reported.

- Bottle roll gold recoveries were not substantially increased compared to the column leach tests indicating that heap leaching is a more attractive option than agitation leaching at this stage of the project.

- Results from cyanide soluble gold assaying of representative samples from throughout the Coffee deposit compare favorably with results from column leach testing of the same sample set (see Table 4) and is being considered as a potentially quantitative method for measuring recoverable gold across all mineralized zones and to depth.

- A preliminary analysis of cyanide soluble data returned from the testing of historical drilling pulps increased the proportion of the resource classified as Oxide at Supremo from a previous visual estimate of 55% to almost 70%, with a further 20% reporting as Upper Transitional Facies. The quantity of Latte Oxide Facies is similar to the previous visual estimation of 25%, with a further 15% reporting as Upper Transitional Facies.

[box type=”note” align=”aligncenter” ]

There are very few compounds that can react with or dissolve gold. This is why gold maintains its lustre while other materials oxidize and tarnish. Sodium Cyanide (NaCN) is one such compound and is used to extract gold in modern mining operations.

There are two tests that were performed for Kaminak. A column leach test involved the addition of reagent to the ore sample in a large vat or “column”. The bottle roll test is similar except that the sample is gently agitated to increase metal recovery. Kaminak is reporting that there was no significant increase in extraction from the bottle roll which indicates that heap leach may be suitable for the processing of their ore. This is good news for Kaminak since heap leaching is an incredibly cheap way to extract gold.

The heap leach process involves the crushing of mined material which is then piled on an impermeable leaching pad. The reagent is usually added to the pile using drip irrigation. The reagent is recycled through the heap for days or even months and the dissolved gold recovered by passing the reagent through activated carbon or resin filters. This process is typically used for extraction from low grade deposits such as those of the Carlin Trend in Nevada.

[/box]

Fred Lightner, Director Mine Development, stated:

“The metallurgical testing results illustrate the amenability of the Coffee deposit to heap leaching, which is typically lower in capital and operating costs than other gold recovery methods. The rapid leaching kinetics, low reagent consumption, lack of agglomeration and the excellent oxide recoveries are most encouraging especially when combined with a requirement for minimal crushing. The results of our 2013 metallurgical program will provide valuable input for the Preliminary Economic Assessment.”

Eira Thomas, Kaminak President and CEO commented:

“This is an important milestone for our project. Not only have we demonstrated that heap leaching represents a viable gold recovery option at Coffee, the cyanide soluble leach assay data will allow us to better map and quantify recoverable gold in the resource block model, which is in the process of being updated, incorporating the results from more than 55,000 metres of new drilling completed in 2013. Kaminak expects to complete and announce an updated NI 43-101 Mineral Resource Estimate early in Q1, 2014”.

2013 Coffee Gold Project Metallurgical Test Work Program

Results of the column leach tests conducted by Kappes, Cassiday and Associates (“KCA”) are summarized below in Table 1.

| Table 1 Simulated Cold Climate (4 Degrees Centigrade) Column Leach Test Results | ||||||

| Sample Description |

Crush Size* inches |

Head Grade g/t Au |

Extracted Grade g/t Au |

Gold Recovery % |

Days Leached | Consumption NaCN kg/t |

| Supremo Oxide | 1.0 | 1.57 | 1.46 | 92% | 40 | 0.17 |

| Supremo Oxide | 0.5 | 1.44 | 1.34 | 94% | 40 | 0.28 |

| Supremo Oxide | 0.5 | 1.55 | 1.47 | 95% | 42 | 0.52 |

| Supremo Upper Transition | 0.5 | 1.49 | 1.08 | 73% | 40 | 0.31 |

| Supremo Lower Transition | 0.5 | 1.67 | 0.80 | 48% | 40 | 0.38 |

| Latte Oxide | 1.0 | 1.62 | 1.46 | 90% | 40 | 0.19 |

| Latte Oxide | 0.5 | 1.54 | 1.38 | 90% | 40 | 0.27 |

| Latte Upper Transition | 0.5 | 1.54 | 0.72 | 47% | 40 | 0.46 |

| Latte Lower Transition | 0.5 | 1.42 | 0.41 | 29% | 40 | 0.64 |

| Latte Sulphide | 0.5 | 2.37 | 0.13 | 5% | 42 | 0.46 |

| *Drill core composites crushed to 31.5 mm (80% passing 1 inch) and 16 mm (80% passing 1/2 inch) |

| **22 degree centigrade test performed at ambient lab temperature |

[box type=”note” align=”aligncenter” ]

Compare 90% gold recovery from the oxide material versus 5% recovery from sulfide material! This is why the oxides are important here. The “transitional” samples are a mixture of sulfides and oxides.

The test was performed in lower temperatures to better simulate the colder conditions of the Yukon, though it is still above freezing. Presumably the heap leaching will need to take place either indoors or outdoors only when conditions are above freezing temperatures. This may mean that ore will need to be stockpiled during the winter months.

[/box]

In the oxide samples, the recoveries of 90% and above were obtained at both a crush size of 0.5 and 1 inch material. Additional test work is currently ongoing to investigate a nominal 6 inch crush size (80% passing 150 mm) for the oxide mineralization at both Supremo and Latte.

[box type=”note” align=”aligncenter” ]

Another cost-advantage of the heap leach process is that ore need only be crushed and not finely ground.

[/box]

Preliminary test work reported no percolation problems; therefore, the use of cement agglomeration was not required. The column leach tests were performed at a temperature of 4 degrees Centigrade to simulate cold climate leaching, with the exception of one test at ambient lab temperature (22 degrees C) as a test control. The gold recovery difference between ambient and cold climate temperature is negligible at 1% (95% versus 94% gold recovery respectively).

All of the samples leached very rapidly with 81.0% and 81.6% gold recovery from Supremo and Latte respectively within ten days leaching of the 1 inch Oxide columns. Low cyanide consumption was reported from all leach columns.

Comparative Bottle Roll Test Work

Results from bottle roll test work undertaken on splits of the same composites utilized for column leaching are detailed below in Table 2. The bottle roll leach tests are somewhat comparable to the column leach tests. By using a fine grind, recoveries were not substantially increased over the column leach tests, indicating that heap leaching will most probably be economically more attractive than agitation leaching.

| Table 2 Results of Bottle Roll Leach Tests | |||||

| Description | Target p80 Size mm |

Head Grade g/t Au |

Extracted Grade g/t Au |

Gold Recovery % |

Leach Time hours |

| Supremo Oxide | 0.075 | 1.44 | 1.36 | 94% | 96 |

| Supremo Upper Transition | 0.075 | 1.45 | 1.13 | 78% | 96 |

| Supremo Lower Transition | 0.075 | 1.64 | 0.87 | 53% | 96 |

| Latte Oxide | 0.075 | 1.57 | 1.45 | 92% | 96 |

| Latte Upper Transition | 0.075 | 1.37 | 0.70 | 51% | 96 |

| Latte Lower Transition | 0.075 | 1.46 | 0.55 | 38% | 96 |

| Latte Sulphide | 0.075 | 2.46 | 0.32 | 13% | 96 |

Sample Composite Selection for the 2013 Metallurgical Test Program

All of the samples used for the column leach tests were composited from drill core consisting of a wide distribution of different drill holes and individual intervals to give a representative sample of each deposit area. Composites were selected at a head grade (see Table 1) close to the global average grade of 1.56g/t Au (base case cut-off) for the 2012 NI 43-101 Coffee Inferred Mineral Resource Estimate. Details of the metallurgical test work composite selection are provided in Table 3.

| Table 3 Metallurgical Composite Selection | ||||||

| Sample Description | Avg. % Fresh Rock |

Sample Type | Core length (m) |

Number of samples |

Number of holes sampled |

|

| Supremo, Oxide | 3 | 1/2 core | 150 | 151 | 16 | |

| Supremo, Upper Transition | 27 | 1/4 core | 127 | 130 | 12 | |

| Supremo, Lower Transition | 71 | 1/4 core | 112 | 112 | 8 | |

| Latte, Oxide | 2 | 1/2 core | 127 | 128 | 15 | |

| Latte, Upper Transition | 35 | 1/4 core | 101 | 97 | 8 | |

| Latte, Lower Transition | 71 | 1/4 core | 95.5 | 96 | 7 | |

| Latte, Sulphide | 99 | 1/4 core | 73 | 72 | 8 | |

Cyanide Soluble Gold Test Work

Categorization of oxidation facies has in the past been undertaken via visual estimation of the proportion of Oxide and Sulphide, followed by the manual interpretation of surfaces and the assignment of oxide facies within the resource block model dependent on whether a block is above or below a certain oxidation surface. The oxidation profile at Coffee is variable, being controlled by the percolation of meteoric water from surface downwards and along the mineralized structures. Thus, the manual interpretation method is unlikely to be detailed enough to accurately assess the quantity and distribution of oxidation facies. In particular, the internal variability within Transitional facies material, which represents a continuum from 5% to 95% oxidized material, is not able to be modelled via the visual method. Presently, the Transitional facies is simply divided into an ‘Upper’ and ‘Lower’ zone based on ≥50% oxidized material and ≤50% oxidized material respectively.

[box type=”note” align=”aligncenter” ]

Kaminak is telling us that it is somewhat difficult to separate the oxide material from the sulfide material using visual observation. In order to better define the zones, they have decided to subject 8,000 samples of previously assayed core to a cyanide solution test. This is why core samples need to be cut into halves or quarters for assays, re-assays and sample libraries. We’ve included a diagram demonstrating the core cuts. They will need to keep at least a quarter core on file for future examination which means that the re-assaying will likely require quarter core samples.

This can sometimes present problems in deposits where the mineralization is not evenly distributed and one half or quarter of a core may not be representative of the full sample. This may be why some of their samples are 1/2 core and others are 1/4. One way to get around this is to use larger core diameters when drilling.

[/box]

In order to better evaluate the amenability and variability of Transitional material to metallurgical cyanide leach recovery, over 8,000 samples representing 70% of all samples above a fire assay value of 0.3g/t Au within mineralized intercepts drilled from the initial drilling year of 2010 up to and including 2013, have been subjected to a cyanide soluble assay. The cyanide soluble assays were performed by ALS Laboratories (Au-AA13 method).

The difference between the cyanide soluble assay and the original fire assay, on an individual assay by assay basis, or across composites made up of equivalent samples, may be utilized to provide an indication of the gold within the sample that is amenable to cyanide leach. By extension, it also indicates the amount of oxidation of the sample. The cyanide soluble proxy gold recovery is the percentage of the fire assay value actually reporting to the leach solution.

A comparison of the column leach test recoveries at the 0.5 inch crush size from the KCA testing program, and the cyanide soluble assays from the same samples as used in the testing composites, is presented in Table 4 below.

| Table 4 Cyanide soluble gold recovery versus column leach gold recovery | |||

| Sample Description | Column Recovery, % Au |

Cyanide Soluble Recovery |

Ratio of Column Recovery to Cyanide Soluble Recovery |

| Supremo, Oxide | 94% | 98.4% | 0.96 |

| Supremo, Upper Transition | 73% | 78.2% | 0.93 |

| Supremo, Lower Transition | 48% | 51.2% | 0.94 |

| Latte, Oxide | 90% | 91.2% | 0.99 |

| Latte, Upper Transition | 47% | 46.5% | 1.00 |

| Latte, Lower Transition | 29% | 32.5% | 0.89 |

The strong correlation of the cyanide soluble recovery and the actual column leach test recovery indicates that cyanide soluble recovery may be a reliable method to map the metallurgical recovery throughout the Oxide, Transitional and Sulphide zones of the Coffee Deposit. Work is ongoing to test the potential for applying this methodology in future iterations of the Coffee Mineral Resource Estimate.

The oxidation profile at Coffee is generally deep, sometimes in excess of 300 meters. Furthermore, all of the mineralization at Coffee currently remains open to depth. From preliminary mineralogical examination of Transitional material at Supremo and Latte, it appears that remnant sulphide mineralization within the Supremo Transitional material has been more efficiently oxidized, and hence, gold extractions from Transitional material at Supremo are comparatively better than those at Latte.

A preliminary comparison of the cyanide soluble assay data against the 2012 NI 43-101 Coffee Inferred Mineral Resource Estimate suggests an increase in the proportion of the Supremo deposit classified as Oxide facies, from a previous visual estimate of 55% to close to 70%, and with a further 20% reporting as Upper Transitional facies. The preliminary analysis suggests the proportion of the Latte deposit classified as Oxide facies is similar to the previously modelled 25%, with a further 15% reporting as Upper Transitional Facies.

[box type=”note” align=”aligncenter” ]

The company is already estimating that the oxide facies rock was underestimated for some zones in previous technical reports. The oxidation appears to extend quite deep due to the percolation of surface water along structural weaknesses and deep into the permeable rock.

[/box]

Sulphide Flotation Testing

In addition to the cyanide leaching test program, KCA also conducted four preliminary rougher flotation tests on the Latte Sulphide sample. Although reagents, grind size and flotation time have not been optimized, gold recoveries varied from 58% to 72% of the gold reporting to a rougher flotation concentrate. Additional work will depend on the future delineation and quantification of sulphide resources.

Kaminak’s disclosure of metallurgical data in this press release has been reviewed and approved by Fred Lightner, P.Eng., Director Mine Development of Kaminak Gold Corporation, who serves as a Qualified Person under the definition of National Instrument 43-101. Disclosure of additional technical or scientific information in this press release has been reviewed and approved by Tim Smith, P.Geo., Vice President Exploration of Kaminak Gold Corporation, who serves as a Qualified Person under the definition of National Instrument 43-101.

[box type=”note” align=”aligncenter” ]

Extraction of the gold from sulfide minerals is an entirely different beast. Before they do more with the sulfides they will need to complete the cyanide assay process and fully delineate the oxide portion of their deposit. If they are lucky the oxides will prove to be a economic project on their own and provide some early cash-flow for future expansion into the sulfide facies rock.

[/box]

[box type=”success” align=”aligncenter” ]Have a company or release you’d like us to look at? Let us know though our contact page, through Google+, Twitter or Facebook.[/box]

Pingback: True Gold Gets Good Karma from Feasibility Study | Geology for Investors