Reverse circulation or RC drilling is a fast and inexpensive method of drilling, particularly compared to diamond drilling. A hundred metres of more of drilling is possible per day. RC is a commonly used drilling method in the mineral exploration industry.

The speed of RC drilling means the drill programme needs to be planned well ahead of drill schedule. The supervising geologist should also have sufficient experience to change the programme at short notice, if necessary.

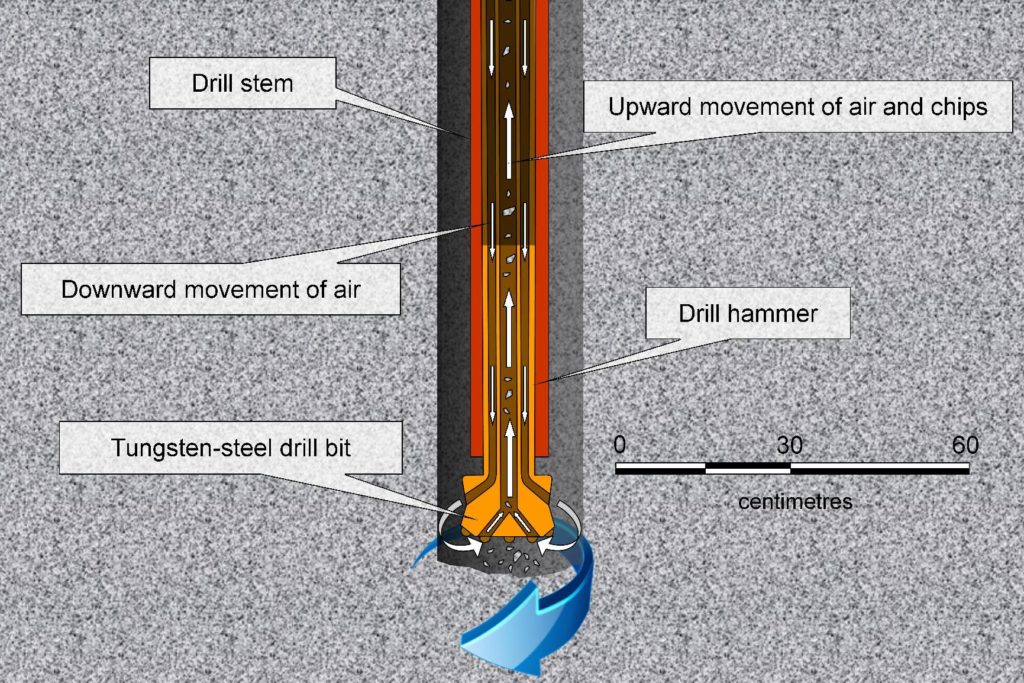

RC drilling works by blasting air down an outer drill pipe using a high performance air compressor at the surface. An air-driven hammer at the end of the drill stem pounds a tungsten-iron drill bit against the rock, pulverising and breaking fragments away. The drill bit, stem and pipe continuously rotate as the rock is being hammered. Jets of air are forced up the drill hole on the side of the drill bit.

Rock dust and fragments known as cuttings or chips are carried by the strong airflow up through the middle of the bit into an inner drill pipe. The air current is so strong that rock material can be brought to the surface from hundreds of metres down. When it reaches the surface, the dust and chips are fed into a cyclone splitter that slows the air flow down and divides the sample into small and large samples.

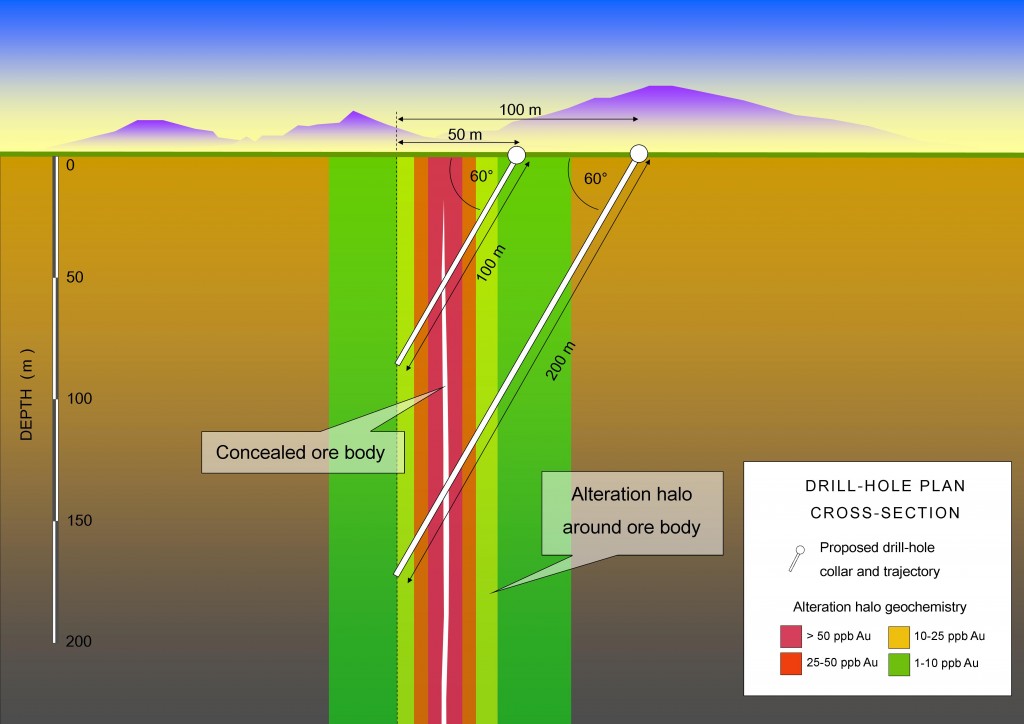

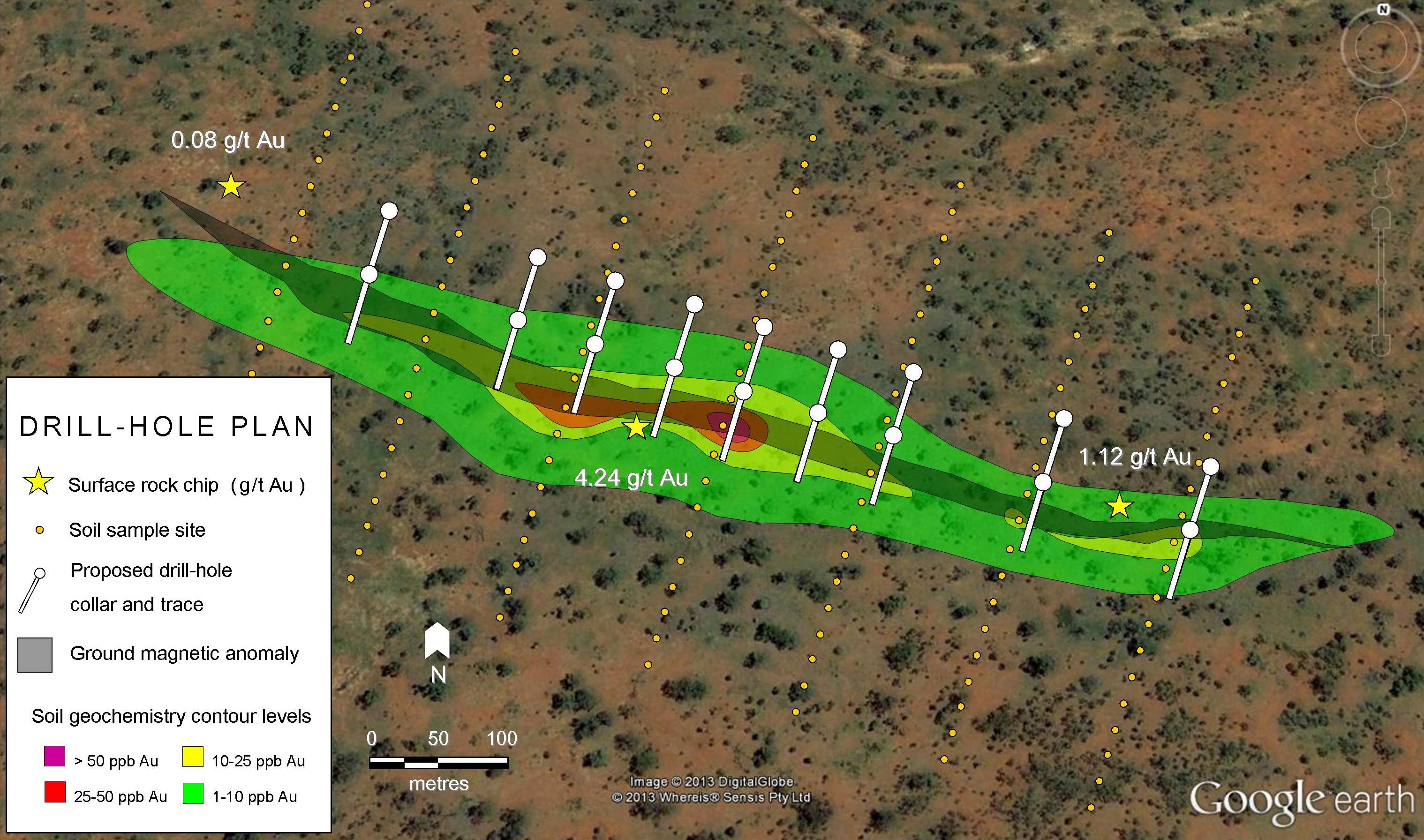

RC Drillhole Planning

The speed of RC drilling means the drill programme needs to be planned well ahead of drill schedule. The supervising geologist should also have sufficient experience to change the programme at short notice, if necessary.

A site inspection by the drilling contractor prior to drilling can iron out issues that may not be apparent to the geologist. Only the driller knows his equipment and its capabilities.

RC Drilling Safety

Reverse circulation drilling has a number of inherent hazards associated with it.

In the past, hearing loss was common among drillers and offsiders as well as geologists and field assistants from being around an operating RC drill rig. The constant hammering of the drill bit through the rock and the loud air compressors combine to make an extremely noisy work place. Occupational health and safety laws now require that workers are protected from this noise. The wearing of hearing protection in the form of earmuffs and earplugs is now mandatory.

Dust is also a hazard. Freshly ground up rock is extremely dangerous when breathed in. When the mineral grains are broken, their fresh surfaces are highly reactive. They can interact adversely with lung linings and other soft tissues. Silicosis, once common among miners, is a chronic lung disease that can result from exposure to crystalline quartz dust. It is essential that workers around a drill rig wear dust masks to prevent silica particles entering their lungs. An even greater risk to health in certain areas is asbestos. Asbestos can be associated with some types of iron ore and nickel sulphide deposits. So, when drilling these types of deposits extra care needs to be taken to protect workers.

The machinery itself can be extremely dangerous. I have heard of reports of tubing coming detached from compressors and cyclones and violently snaking around, seriously injuring workers. To protect eyes, safety glasses must be worn at all times. A hard hat, high visibility clothing, steel capped boots and gloves are also extremely important.

Sample bags are normally very heavy so care needs to be exercised when carrying these, otherwise back injuries can result.

Sampling of RC Drilling

Most RC drill rigs have a splitter attached to or incorporated within the cyclone. The job of the offsider is to attach bags to the two outlets of the cyclone to collect samples. A small bag collects a sub-sample whilst a large bag collects the rest of the sample. When the samples are collected the smaller one is taken to where the geologist is set up. The larger sample is normally stored on-site together with others in neatly arranged rows. These are kept until all the necessary laboratory analyses have been done. The smaller bag is the one that goes to the laboratory. Both bags are labelled with the same unique number. This is obtained from a ticket book or by another foolproof method. Due to the fast pace, it is best to pre-number bags otherwise mix-ups may occur.

A common practice to reduce laboratory analysis costs is to group three consecutive samples together into what is known as a 3-metre composite. Although cheaper, this method does reduce the accuracy of the sample assay. When the laboratory has issued the results, the geologist then decides whether to submit any of the individual metre intervals for analysis. This normally happens if mineralisation is detected in the composite samples and improved resolution is required.

Reverse Circulation Sample Logging

Samples from RC drilling are composed of broken up pieces of rock called chips. These individual pieces of rock are around 10 millimetres in size. As well as chips, there is much fine grained material as well.

The field assistant normally puts some of the sample from the large bag into a plastic sieve for the geologist. A wash and sieve may be done by the field assistant or by the geologist. The geologist inspects the contents of the washed rock chips using a hand lens and quickly describes the rock and records the information on a logging form or directly onto a computer. Most of the time, the geologist can only spend a couple of minutes on each sample. Therefore, usually a quick look and short description is all that can be done. After logging each sample a representative portion is placed into a pre-numbered plastic RC chip tray for future reference.